Guide to Thermoforming Food Packaging : Everything You Need to Know

2021/09/16What is Thermoforming Food Packaging?

Thermoforming Food Packaging is a process where a plastic sheet is heated to a pliable temperature and formed to a desired container shape with barrier properties for excellent food preservation and protection. There are various kinds of thermoforming materials used for the food packaging, including PP, PET, PS, PLA and CPLA. Different materials require different temperature settings. In order to make the desired food packaging shapes, for optimal material distribution, it is not only necessary to have a perfect machine parameter setting, but you also need efficient forming molds with optimal air and cooling systems. Once a plastic sheet is thermoformed at the forming station, it is transported to the trimming station where the thermoformed container is cut and trimmed. The final Thermoformed Food Packaging is then created.

Design Considerations of Thermoforming Food Packaging

Efficient Tooling Process

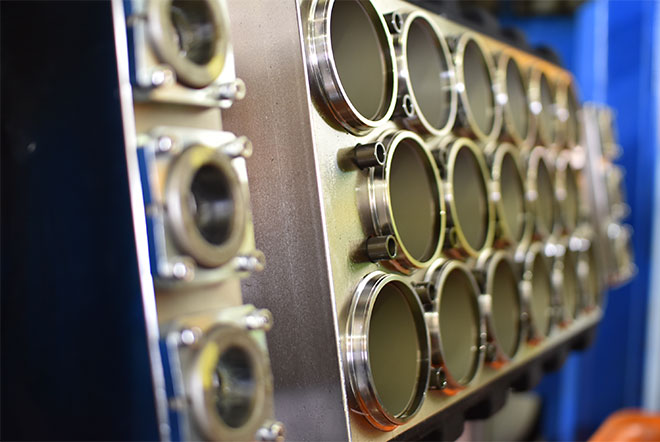

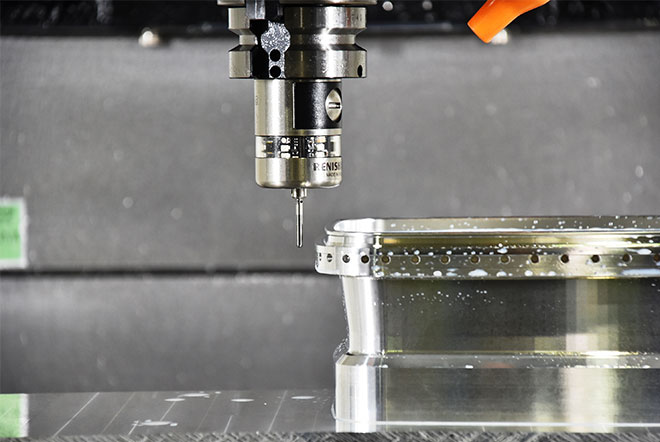

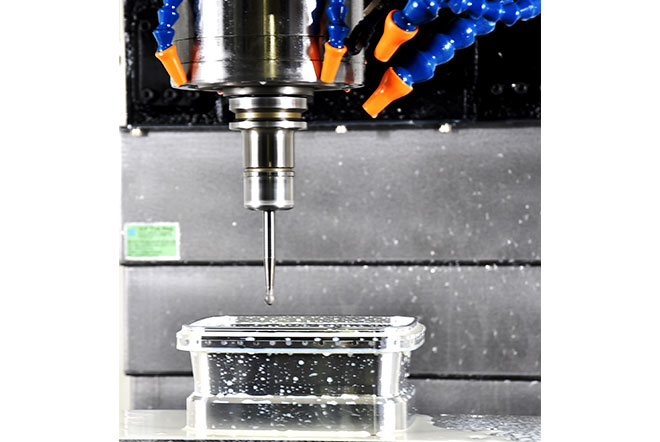

Thermoforming Molds play a pivotal part in optimizing the thermoforming process. Partly because of consistent production output and partly because of flawless food packaging containers. Developing a high-quality thermoforming mold in a shorter amount of time will expedite the process of launching new products. Only a qualified Thermoforming Mold Maker can offer you a one-stop solution, with services ranging from product design to mold trial-testing. In addition, to maximize the production output, there are some critical considerations to thermoforming food packaging mold designs including mold layout, demolding systems, cooling systems, air systems, etc. To choose an experienced tool expert who can design a robust packaging mold structure with extremely precise manufacturing capability is an essential element for successful food packaging production.

Constant Forming and Cutting Quality

In thermoformed food containers for the food processing and food service industries, such as cups, containers and clamshell packagings, high performance tooling design and technology improves cutting precision and parallelism stability. When the relationship between you and mold or machine vendors moves forward, a qualified vendor will be able to provide valuable customer service ! It is important that the vendors present other ways to achieve your goals, and do due diligence on solving your challenges. The more steps you take up front to minimize risks, by utilizing experienced mold makers, the more competitive and profitable you will be.

Productivity and High Flexibility

No product can be made while production is waiting for maintenance to repair equipment or while a mold changeover is taking place. Utilizing multiple core and cavity sets on a common mold base with a quick mold change system has many benefits. With the use of a common mold base, capital investment is reduced. Only the core and cavity sets are needed to be purchased. Hong Zu Thermoforming Food Packaging Mold designs ensure that you are able to quickly change-over core/cavity inserts without causing additional production delays. Our thermoforming molds support a flexible manufacturing system. The tooling designs are easily adapted to changes in the different types of thermoforming machines and tooling.

The Most Common Designs of Plastic Thermoforming Food Packaging

Low cost of tooling and production are two advantages of the thermoforming process for Plastic Food Packaging. Lower costs and fast prototyping are also advantages leading to shorter production lead times. Whatever complexity of the custom molds, pressure, vacuum or plug assist Thermoforming Processes are superior. Most common Examples of Thermoforming Food Packaging are plastic trays, cups, containers and clamshells. These container solutions attractively display and protect consumable products, and they are products used by consumers in daily life.

-

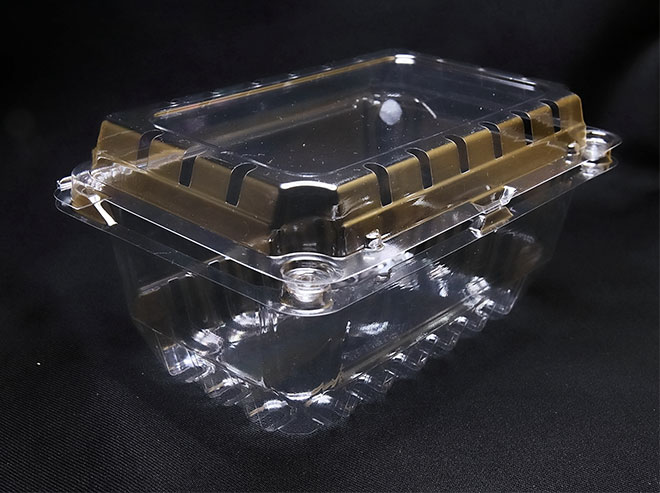

Thermoformed Clamshells

Thermoformed clamshells offer protection, organization and effective presentation to the products. Compared to the thermoformed trays, thermoformed clamshells do not require additional packaging to function. These are often transparent and the products can be easily viewed. Optimizing the ventilation design of food packaging is crucial for improving the efficiency of the forced-air precooling process to maintain the quality of horticultural produce and extend the shelf life in the food cold chain. You can also add innovative designs to your food clamshells, for examples, a seal that goes all the way around the outside of the package for dry foods, creating a perfectly airtight closure that prevents theft and product tampering.

Read Also : "Clamshell Packaging Design : A Guide to Choosing the Right Mold"

-

Thermoformed Cups

PET / PP / PS / PLA are common plastics for Thermoformed Cups. High performance In-Mold Cut Molding is the best vacuum forming process. It provides higher output and lower energy consumption. Plugs are used in almost all tools designed for cup production. Having qualified toolmakers and thermoformers understand the challenges associated with creating the perfect cup plug for you is the best solution for making cups.

Read Also : "Plastic Cup Molding : Thermoforming VS Injection Molding"

-

Thermoformed Containers

Thermoformed containers are usually used in restaurant & food service industries. These disposable plastic food container designs (made from PP, PS or PET) combine numerous features : a hinge that alerts if tampering has occurred ; a leak-resistant design ; tight seals and tabs which are made for easy opening and closing.

-

Thermoformed Tray

Trays are commonly used for food packaging and by the food serving industries. These trays can hold a variety of foods, such as salad and meat. It is important to strive to find the best compromise between tray design and material thickness in order to save cost, while meeting performance and quality requirements.

Molds and Equipment for Thermoforming Food Packaging

The Food Packaging Thermoforming Process requires a few pieces of equipment. The forming process needs either pressure formers or vacuum formers. You will need large flatbed thermoforming molds, small format molds, trim tooling, trim-in-place inline & tilt-bed tooling, cut knife tooling or multi- motion tooling for all major thermoforming machines including ILLIG, WM, KIEFEL, GN, ABLER, AMUT, LYLE, BM, TSL, SENCORP, T2, IRWIN, CHENG MEI, CHUDONG, ASANO, SENBA, TRURAN-CHULIING, SUNWELL, VFK, GAMBLER, ILLIG,INPAK,YM, ASANO, etc.

The Most Common Plastic Materials of Thermoforming Sheet for Food Packaging

Many plastic sheet materials can be shaped by thermoforming. At Hong Zu, we understand the unique benefits offered by different types of thermoforming materials. To help you understand your options and which kind might be the best fit for your food packaging projects.

-

PLA/CPLA

-

PP/CPET

-

PET/PS/OPS

Thermoforming Food Packaging Mold Design & Manufacturer

Hong Zu is one of the leading custom mold makers for Thermoforming Food Packaging in Taiwan. We provide innovative packing mold solutions that include every stage of tooling design and manufacturing, from initial proposals to the finished molds. We are also a pioneering mold manufacturer that manages and integrates mold production chains by intelligent manufacturing planning. By having a digital twin of the factory, it is possible to simulate beforehand new productions and understand the bottlenecks. Therefore, Hong Zu can have better control of the overall process, rapid response to process anomalies and ensure on-time delivery, making you more competitive. We serve both the food processing and food service industries. When you need any packaging solutions, our team has experience designing custom solutions that protect your food and reputation! Please contact us to start your thermoforming food packaging project.

If you want to know more about these and our other products, please check the link below. Thermoforming Mold

To keep updated about the latest news from the Hong Zu, please follow us on our Social Media Channels :